"Simplicity is the greatest sophistication."

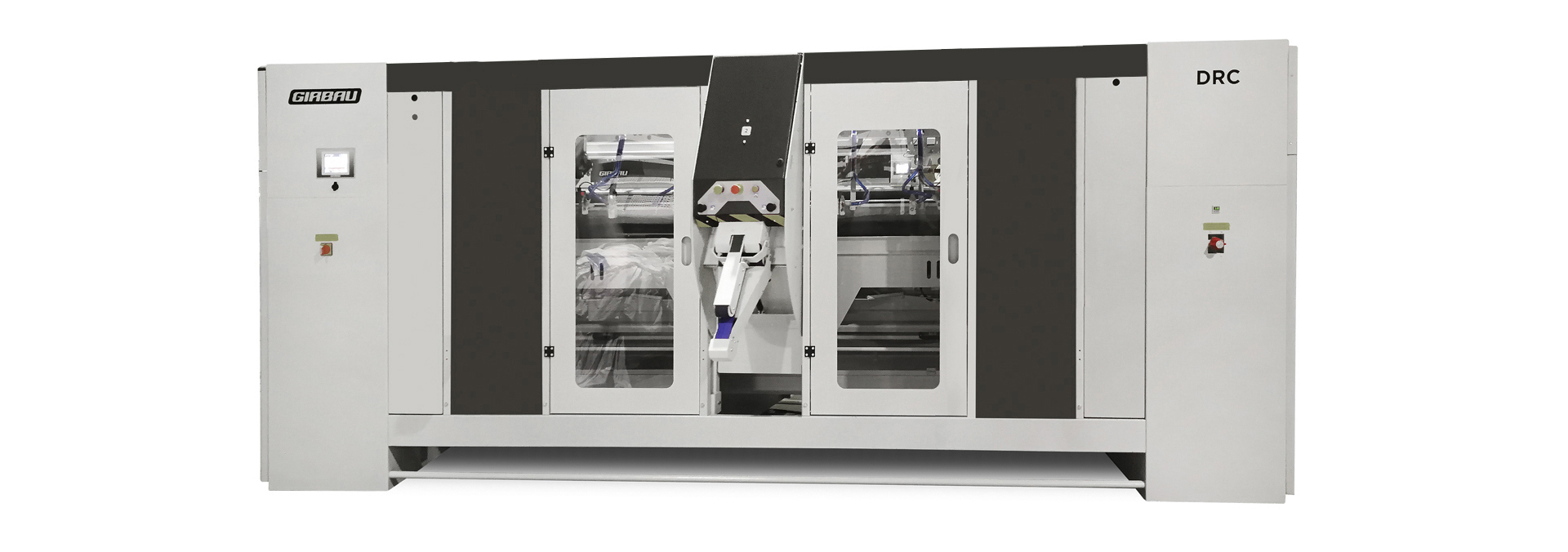

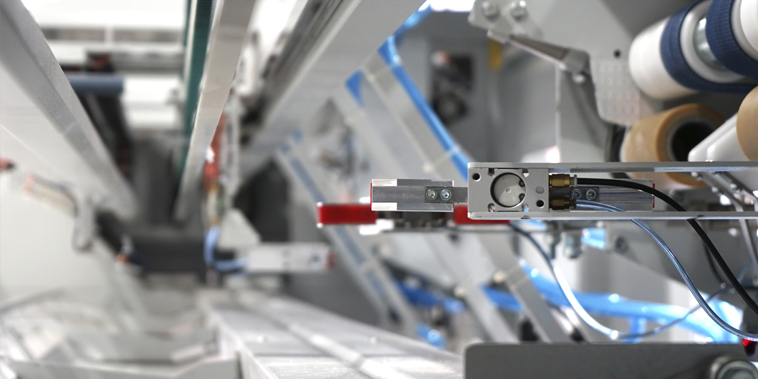

Thanks to the DRC Feeder, the corners of the sheets are no longer important

We started with the problem. Operators often struggle to efficiently find the corners of sheets in order to initiate the feeding process. Solving this problem was key, and why we developed Girbau's DRC Cornerless Feeder. Designed for the rapid insertion of single bed sheets, with particular attention to optimizing production, this feeder combines superior speed with Girbau's exclusive technology for feeding without corners. Now operators don't have to find the two corners of a sheet before inserting it. So by solving a problem, we have doubled operator feeding productivity!

1 Station

Up to 600 bed sheets per hour

2 Stations

Up to 1300 bed sheets per hour

3 Stations

Up to 1500 bed sheets per hour

Efficiency

Quality

Speed

Cost

Programmable control

Easy maintenance

Doubled operator feeding rates

Girbau's exclusive patent makes the DRC the only feeder on the market capable of working in 2 ways, without the operator having to locate the corners of bed and table linens before insertion. And this translates into speed: The DRC Cornerless doubles feeding output per operator, compared to the traditional method of finding corners and placing them into the feeding clips.

Maximum versatility and a drop rate of less than 2%

The DRC quickly feeds small- to large-dimension items into corresponding ironers. It provides laundries with high-quality feeding, a drop rate of less than 2%, low maintenance, and an ideal relationship between production and air consumption.

More than 600 pieces / hour per operator station in 1 or 2 lanes

The DRC offers 1 or 2 lane operation with 1, 2 or 3 operator feeding stations. It’s the only cornerless feeder on the market with 2 lane productivity, which creates a 25% increase in linen surface area, compared with working in 1 lane. This drastically improves production.

Achieve production of more than 600 items per hour for each feeding station.

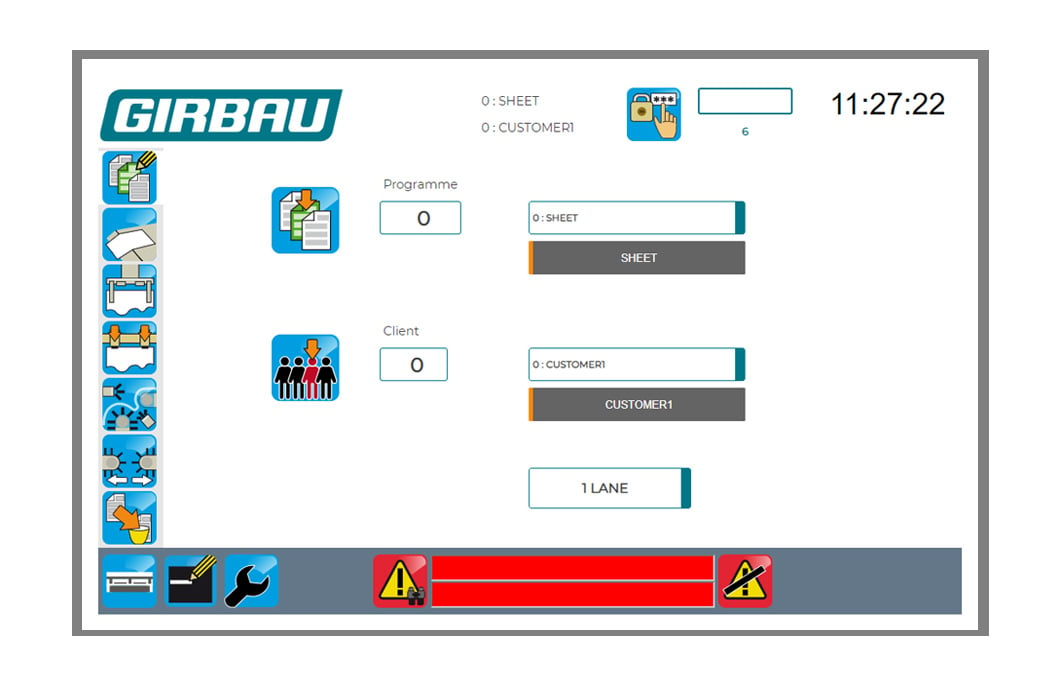

The DRC PLC-control system represents our most advanced Human Machine Interface (HMI), with its 10 inch touchscreen for optimum control of feeding parameters. With up to 99 programs, a fast processor, multiple languages, remote upgrading and an option for remote system service, it’s Girbau’s most user-friendly, intuitive control ever.

Accessibility and productivity control

The DRC’s cleaning and maintenance is easy thanks to quick access from the side panels and front doors. This reduces maintenance costs and downtime.

All main components are accessible from the DRC’s side cabinets, while the pneumatic feed table is accessible, and can be cleaned, from the rear of the DRC.

Optional Counters

An optional counter system for real-time production is available on the DRC. The counter tracks production on each station independently.

Maximum safety for your operators

The DRC, a fully enclosed machine with protected accesses, features easy visibility from the outside. Clear visibility eliminates the need to remove guards or open covers. This not only reduces risk to operators, it reduces risk to the property.

Download your brochure